Calculation of operating clearance

Operating clearance of a bearing can be calculated from initial bearing internal clearance and considering the decrease in clearance due to fitting and the difference in temperature of the inner and outer rings.

Δ e = Δ 0 -(δf + δt )=Δ f -δt ………(8.1)

Where:

Δ e : Effective internal clearance, mm

Δ 0 : Bearing internal clearance (initial), mm

Δ f : Residual clearance (clearance after preloading), mm

δf : Reduced amount of clearance due to fitting, mm

δt : Reduced amount of clearance due to temperature differential of inner and outer rings, mm

(1) Reduced clearance due to fitting

When bearings are installed with interference fits on shafts and in housings, the inner ring will expand and the outer ring will contract; thus reducing the bearings’ internal clearance.

The amount of expansion or contraction varies depending on the shape of the bearing, the shape of the shaft or housing, dimensions of the respective parts, and the type of materials used. The differential can range from approximately 70% to 90% of the effective interference.

δf = (0.70 〜0.90) Δ deff ……………(8.2)

δf : Reduced amount of clearance due to interference, mm

Δ deff : Effective interference, mm

(2) Residual clearance

When the reduced clearance due to interference is calculated using the expansion rate and the contraction rate of each bearing, the residual clearance is calculated by the formula below.

1) Calculation considering distribution

Assume that the initial clearance, bearing inner ring bore diameter, bearing outer diameter outer diameter, bearing outer diameter, and housing bore diameter follow the normal distribution. The residual clearance is generally calculated as the range of percent defective. When each dimension and clearance follow the normal distribution and the percent defective is 0.26% (standard range = ±3σ), residual clearance Δ f can be represented by the formula below.

∆ f = ∆ fm ± 3σ∆ f ……………………(8.3)

Where:

Δ fm : Average value of standard clearance, mm

σΔ f : Standard deviation of residual clearance

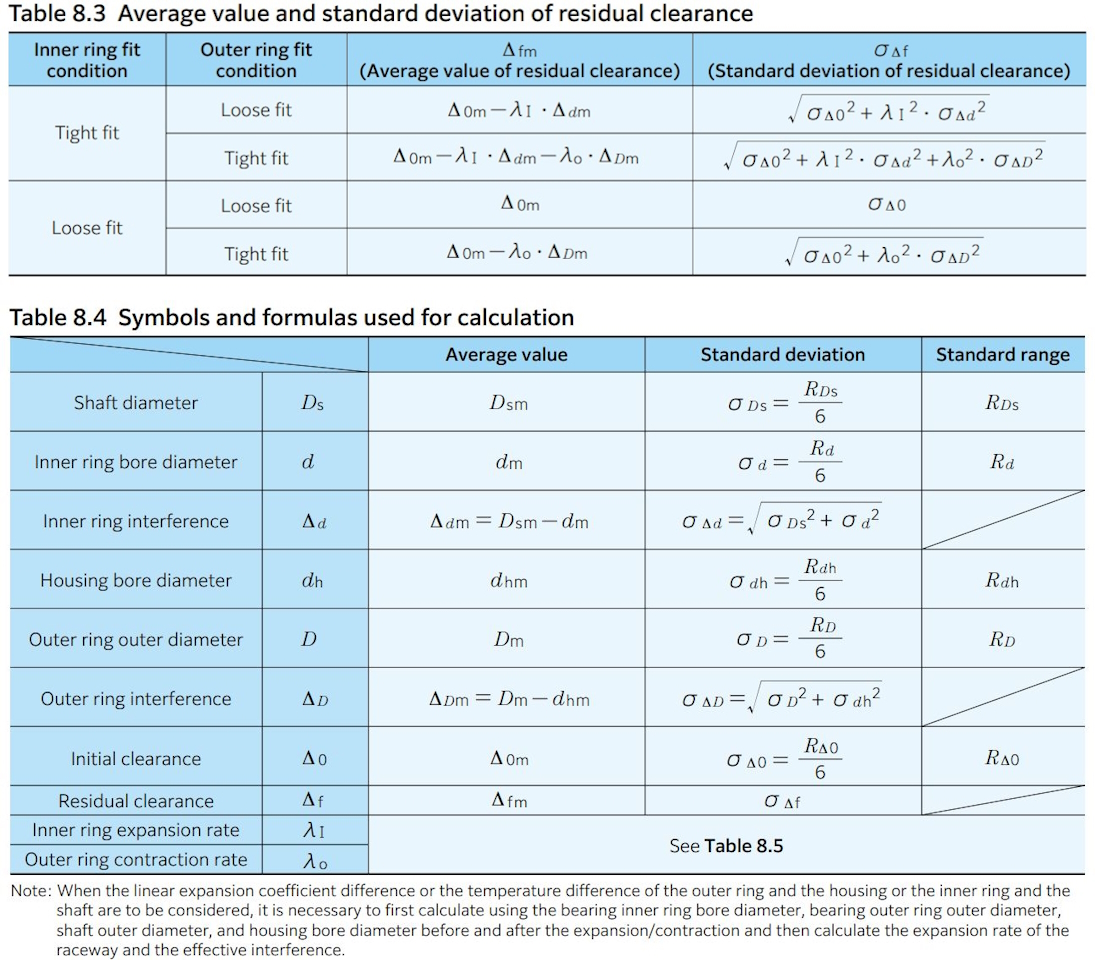

For the average values and standard deviation of residual clearance, see Table 8.3 and Table 8.4.

2) Calculation by direct sum

When the use condition is severe and calculation is to be done under the worst condition, the maximum and minimum values of each dimension are used for direct sum.

∆ f max = ∆ o max -λi ∆ d min -λo ∆ D min (8.4)

∆ f min = ∆ o min -λi ∆ d max -λo ∆ D max (8.4)

∆ f max ∆ f min : Maximum and minimum values of residual clearance, mm

∆ o max ∆ o min : Maximum and minimum values of initial clearance, mm

∆ d max ∆ d min : Maximum and minimum values of inner ring interference, mm

Δ D max Δ D min : Maximum and minimum values of outer ring interference, mm

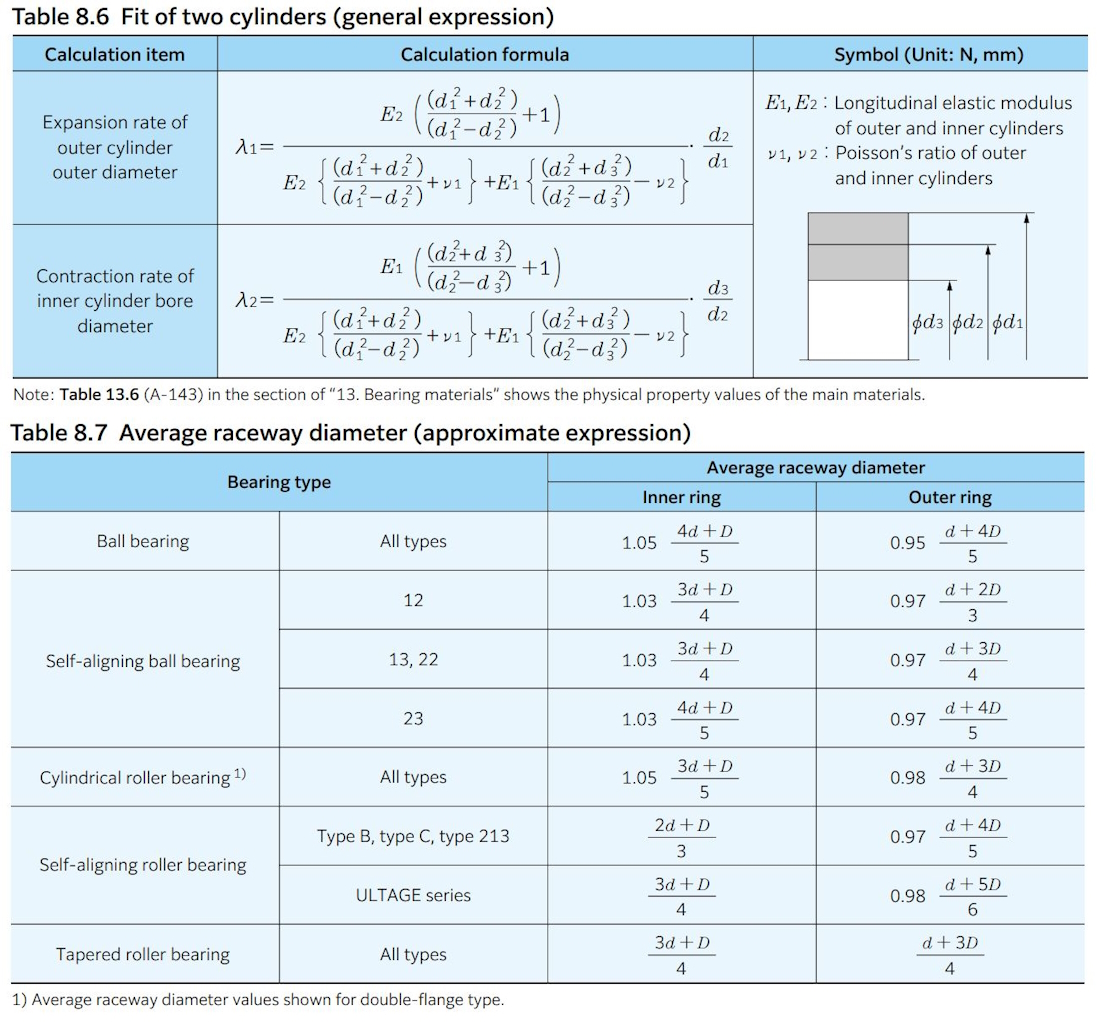

λi λo : Inner ring expansion rate, outer ring contraction rate (See Table 8.5)

(3) Reduced internal clearance due to inner/ outer ring temperature difference.

During operation, normally the outer ring will range from 5 to 10°C cooler than the inner ring or rotating parts. However, if the cooling effect of the housing is large, the shaft is connected to a heat source, or a heated substance is conducted through the hollow shaft; the temperature difference between the two rings can be even greater. The amount of internal clearance is thus further reduced by the differential expansion of the two rings.

δt = α・Δ T・Do ……………………(8.5)

δt : Reduced amount of clearance due to temperature differential of inner and outer rings, mm

α : Bearing material expansion coefficient 12.5 × 10-6/°C

Δ T : Inner/outer ring temperature differential, °C

Do : Outer ring raceway diameter, mm

Outer ring raceway diameter, Do, values can be approximated by using formula (8.6) or (8.7).

For ball bearings and spherical roller bearings,Do = 0.20(d + 4.0D) …………………(8.6)

For roller bearings (except spherical roller bearings),

Do = 0.25(d + 3.0D) …………………(8.7)

dw : Bearing bore diameter, mm

Dw : Bearing outside diameter, mm

For the ULTAGE series bearings, consult NTN Engineering.

Note that the formula in item 8.2.2 only applies to steel bearings, shafts and housings.

“Operating clearance calculation (based on 3σ)” can be done by using the bearing technique calculation tool on the NTN website (https://www.ntnglobal.com)