Grease replenishment

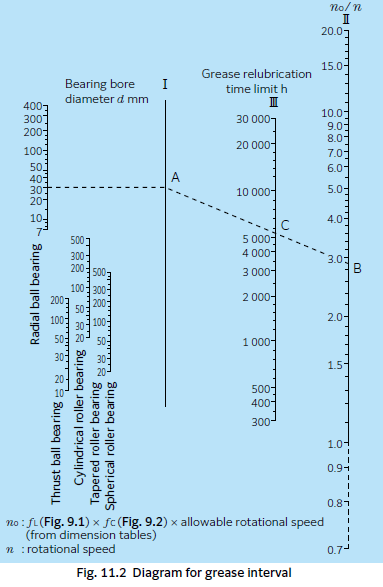

As the lubricating performance of grease declines with the time, grease must be filled in proper intervals.The replenishment interval depends on the type of bearing, dimensions, bearing’s rotating speed, bearing temperature, and type of grease. An easy reference chart for calculating grease replenishment interval is shown in Fig. 11.2. This chart indicates the replenishment interval for standard rolling bearing grease when used under normal operating conditions. As operating temperatures increase, the grease interval should be shortened accordingly. Generally, for every 10°C increase in bearing temperature above 80°C, the grease interval period is shortened to “2/3”.

For grease replenishment interval of the ULTAGE series, please contact NTN Engineering.

(Example) Find the grease relubrication time limit for deep groove ball bearing 6206, with a radial load of 2.0 kN operating at 3 600 min–1

From Fig. 9.1 Cr / Pr = 21.6 / 2.0 kN = 10.8, fL = 0.96. Allowable rotational speed from the dimensions tables for bearing 6206 is 11 000 min–1. Allowable rotational speed no for 2.0 kN radial load is:

no = 0.96 × 11 000 = 10 560min−1

Therefore, no/n = 10 560/3600 = 2.93

The point where vertical line Ⅰ intersects a horizontal line drawn from the point equivalent of d = 30 for the radial ball bearing shown in Fig. 11.2 shall be point A. Find intersection point C where vertical line Ⅲ intersects the straight line formed by joining point B (no / n = 2.93) with A by a straight line Ⅱ. It shows that grease life in this case is approximately 5,500 hours.

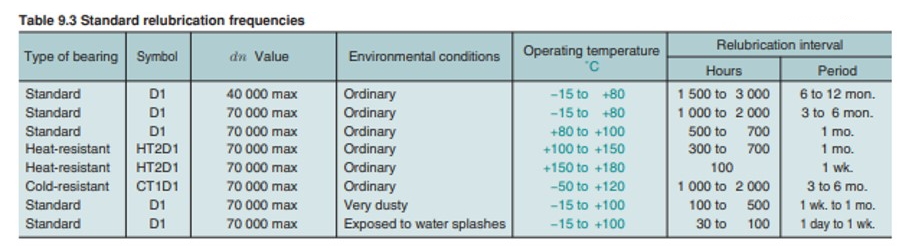

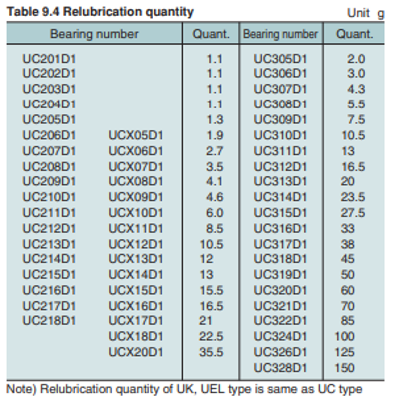

Relubrication frequencies for bearing units